Nowadays you can get a 4,400 liter, 3 meter wide, metal frame above ground swimming pool for 99 EUR. Inflatable models with the same capacity sell for less than 60 EUR - and that includes filtration ! But it is easy to spend a lot more on add-ons than on the pool itself, for the sake of doing a bit of applied science in one's backyard. This article is a collection of back-of-the-envelope calculations about mechanical design, thermodynamics and chemistry in relation to garden swimming pools.

Historically, small kiddie pools were built as a cylindrical stack of inflatable rings.

Modern designs have an inflatable ring at the top and a tapered wall. One might think that the ring floats at the surface and pulls the wall up. Actually, the ring merely keeps the top edge circular, and it is hydrostatic pressure that pushes the wall up.

Metal frame pools have a vertical wall suspended from a polygonal frame made of tubes and angled connectors, mounted on vertical poles. This is probably the safest type: young children can easily hold on to the frame, whereas they might fail to grasp the thick and slippery edge of an inflatable model.

For numerical calculations we will assume:

- Overall diameter: 3.05 m

- Water quantity: 4,400 kg

- Water surface: 6.5 m²

- Water height: 0.68 m

- Ambient temperature: 20°C (293 K)

- Target water temperature: 30°C (303 K)

- Heat capacity: Cp = 4180 J/kg/K

- Latent heat of vaporization: L = 2260 kJ/kg

The side wall of these pools is typically made of two layers of PVC laminated to an inner polyester mesh. It must be strong enough to resist hydrostatic pressure.

Thin-walled cylindrical pressure vessels are dimensioned according to the formula S=P*r/t where S is circumferential stress, P is inner relative pressure, r is radius of curvature, and t is wall thickness.

Here r = 1.5 m, P = 6800 Pa at the bottom, and t = 0.71 mm. So the tensile strength of the liner should be at least 14 MPa. This is consistent with polyester having a tensile strength of 55 MPa.

According to the same formula, the largest model in the product range should have a liner about 5 times as thick, i.e. between 3 and 4 mm, for a diameter of 7.92 m and a water height of 1.17 m.

It takes 184 MJ (51 kWh) to raise the water temperature by 10 K. Assuming 0.15 EUR/kWh, a 3 kW pool heater can do the job in 17 hours for 8 EUR. Afterward, the heater still needs to compensate for losses.

For comparison, the cost of filling the pool with tap water is 19 EUR.

Heat pumps are available for small residential swimming pools ! Manufacturers recommend 3 kW for pools up to 12 m³ and 12 kW up to 60 m³, which might be undersized unless the intent is only to compensate for heat losses. The rated coefficient of performance is between 4 and 5.

A solar cover (a.k.a. solar blanket) is a sheet of plastic material that looks like bubble wrap and floats on the surface of the pool. The name suggests that its purpose is to capture sunlight, possibly like a greenhouse would. But this does not make much sense, as water itself is very good at absorbing infrared radiation.

Presumably the actual function of these covers is to reduce heat loss:

- The air inside the bubbles creates an insulating layer against heat loss by conduction.

- The cover acts as a barrier against evaporation. Evaporative cooling is a very significant phenomenon: Whenever 1 % of the water evaporates, the temperature drops by 5 K.

Solar collectors intended for use as pool heaters are essentially panels of black polyethylene with water ducts running through them.

A solar collector receives up to 1100 W/m² from direct and indirect sunlight. According to Stefan's law, at 303 K, the collector itself radiates 480 W/m². The bottom side of the collector receives 420 W/m², assuming the ground and environment radiate like a blackbody at 293 K. So the maximum net gain is 560 W/m². This figure drops to 240 W/m² at 45° incidence, and almost 0 at 60° incidence. Insulating the bottom side of the collector would significantly improve this.

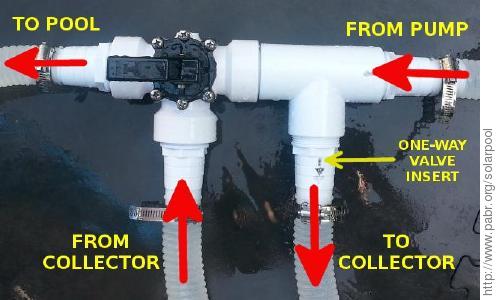

At night the solar collector would act as a radiative cooler, wasting about 500 W/m² under a cloudless sky. This is avoided by disconnecting the collector from the filtration circuit with a manually-operated bypass valve.

There are several motivations for installing solar collectors vertically:

- Not enough space available on the ground

- Ground is shaded by trees or buildings

- Capturing heat in the morning when the sun is low on the horizon.

Here are the issues that need to be addressed:

Filtration pumps generate only about 1 meter of head. Therefore air must be flushed and prevented from re-entering the circuit. Otherwise the flow will be interrupted and the pump may overheat.

Air is best flushed by injecting water at the bottom of the circuit, e.g. by connecting a garden hose, but care must be taken to avoid over-pressurizing the collectors; their rated maximum pressure is about 1 bar.

Pressure at the top of the circuit will be below atmospheric pressure. This may cause problem with plumbing connectors that are designed for positive pressure. For example, the quick connect fittings which are commonly found on garden hoses are not watertight under negative pressure.

And here is one way to implement a vertical collector:

Attach a transparent bubble trap and a one-way valve at the highest point of the circuit.

Attach a ball valve and fitting for a garden hose at the bottom.

Install the bypass valve at the egress of the collector, rather than at the ingress.

Add a one-way valve at the ingress of the collector.

With this configuration, it is possible to disconnect the collector from the filtration circuit, and safely flush air by injecting water at the bottom.

Presumably a significant portion of heat losses is caused by conduction to the ground. Suppose the pool is installed on a 13 mm thick EVA foam mat. Assuming the ground is at ambient temperature and EVA foam has the same thermal conductivity as polyurethane foam (0.02 W/m/K), this reduces losses to 15 W/m² (0.02 K/h). Assuming instead that the weight of the pool compresses the foam into a 5 mm layer with the same thermal conductivity as solid EVA (0.34 W/m/K), heat loss would be 680 W/m² (0.9 K/h). In practice, dry soil would provide additional insulation.

The foam mat also protects the pool liner from sharp rocks and other debris which are hard to find until the pool has been filled.

The pool and solar collector should be positioned optimally after taking into account Sun ephemerides for the specific location and time of year, statistical climate data, and 3D models of surrounding trees and buildings. But maybe this would be going too far into over-engineering territory.

A garden swimming pool is a massive chemical reactor whose parameters must be controlled throughout the summer season. Although this is not as challenging as managing a large in-ground pool over several years, the chemistry involved is interesting.

The water must be disinfected and must remain safe even as a constant stream of biological contaminants enter the pool: parasites, bacteria, viruses, spores, cysts.

The water must be aesthetically pleasing. Algae proliferate under sunlight and give a green tint. Particles and colloidal suspensions cause turbidity.

The water must not have an unpleasant smell.

Here is an overview of some of the techniques involved:

Mechanical filtration, either through sand or through a synthetic cartridge, removes solid particles above a certain size (typically 10-20 µm).

Chlorination is a well known water disinfection technique. [ NaOCl → Na+ + ClO- ].

Reaction with nitrogen compounds (such as sweat) produces chloramines, which are responsible for the characteristic smell of chlorinated swimming pools. [ NaOCl + NH3 → NH2Cl + NaOH ], [ NaOCl + NH2Cl → NHCl2 + NaOH ], [ NaOCl + NHCl2 → NCl3 + NaOH ].

Electrochlorination consists in adding sodium chloride to the water so as to produce hypochlorite on demand by electrolysis: NaCl + H2O → NaOCl + H2.

Sodium troclosene (DCCNa) dihydrate (CAS 51580-86-0) releases chlorine slowly; it remains effective for several days.

N,N-diethyl-p-phenylenediamine sulfate (DPD) is used to measure the concentration of free chlorine and other oxidizers.

Excessively high pH causes carbonates to precipitate, making the water milky white. Besides, at high pH, chlorine is in the form of hypochlorite ions (OCl-), which are weaker than hypochlorous acid (HOCl) as a disinfectant. pH is commonly lowered by adding sodium bisulfate (NaHSO4) (CAS 7681-38-1), i.e. partially neutralized sulfuric acid.

Excessively low pH causes Cl2 to bubble out of the pool rapidly. pH is commonly raised by adding sodium carbonate (Na2CO3) (CAS 497-19-8).

Bromination and peroxide based techniques are sometimes used as an alternative to chlorination.

Clarifying agents can be added to trigger flocculation of suspensions and precipitation of dissolved contaminants, after which they can be removed by mechanical filtration.

In general, water purification also includes the removal of other contaminants such as dissolved gasses, heavy metal, pesticides and hydrocarbons, but these are unlikely to be a concern in a swimming pool that has been filled with tap water.